Stable and reliable power supply: relying on cable reels to retract and retract cables for power supply, the power transmission is continuous and stable, avoiding the problem of limited battery life and adapting to long-term continuous operation.

| 0-10 |

|

BJT-2t |

BJT-20t |

BJT-50t |

BJT-100T BJT-150t | |||

|

Rated Load(t) |

2 |

20 |

50 |

100 |

150 |

|

|

Table Size(mm) |

Length(L) |

2000 |

4000 |

5500 |

6500 |

10000 |

|

Width(W) |

1500 |

2200 |

2500 |

2800 |

3000 |

|

|

Heigth(H) |

450 |

550 |

650 |

900 |

1200 |

|

|

Wheel Base(mm) |

1200 |

2800 |

4200 |

4900 |

7000 |

|

|

Rail Inner Gauge(mm) |

1200 |

1435 |

1435 |

2000 |

2000 |

|

|

Wheel Diameter(mm) |

270 |

350 |

500 |

600 |

600 |

|

|

Wheel Quantity |

4 |

4 |

4 |

4 |

8 |

|

|

Ground Clearance(mm) |

50 |

50 |

50 |

75 |

75 |

|

|

Running Speed(min) |

0-25 |

0-20 |

0-20 |

0-20 |

0-18 |

|

|

Motor Power(kw) |

1 |

2.2 |

5 |

10 |

15 |

|

|

Battery Capacity |

180 |

180 |

330 |

440 |

600 |

|

|

Battery Voltage |

24 |

48 |

48 |

72 |

72 |

|

|

Running Time When Full Load |

4.32 |

4 |

3.3 |

3.2 |

2.9 |

|

|

Running Distance for One Charge(Km) |

6.5 |

4.8 |

4 |

3.8 |

3.2 |

|

|

Max Wheel Load(KN) |

14.4 |

77.7 |

174 |

343.8 |

265.2 |

|

|

Reference Weight(t) |

2.8 |

5.9 |

8 |

14.6 |

26.8 |

|

|

Recommended Rail Model |

P15 |

P24 |

P43 |

QU100 |

QU100 |

|

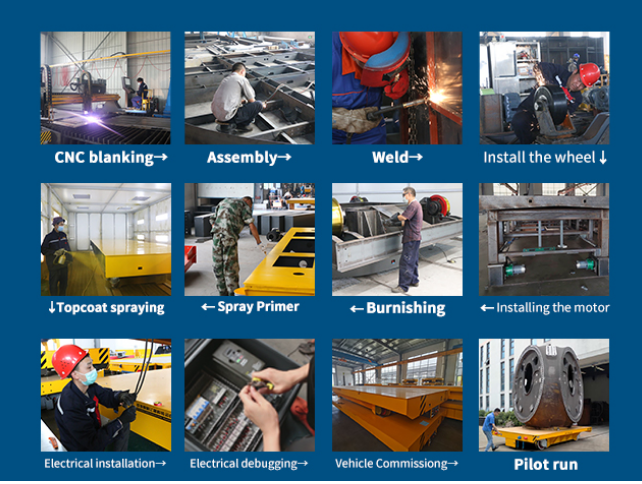

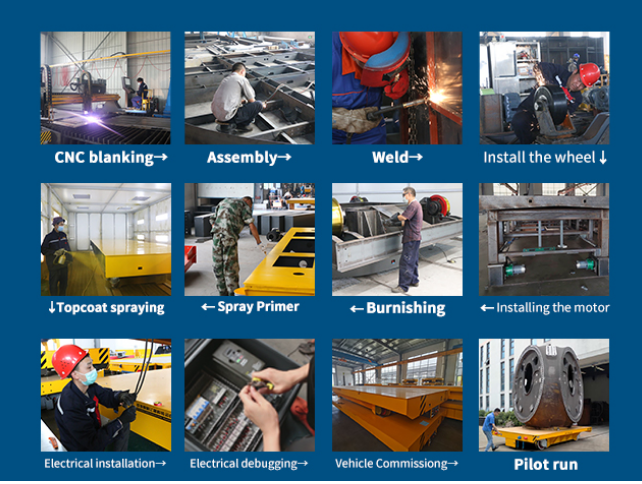

Process

-

360 degree motorized rotation without causing any damage to the floor.

-

Powered by storage battery, turning freely without any cable strings.

-

Controlled easily by pressing the buttons and speed controller.

-

High level automation(self propelled/steerable)

-

The largest capacity can reach to 100t

-

Safe parts are installed in the transfer cart(warning light, e-stop, buffer...)

-

Robust sturdy car frame

.jpg)

.jpg)

.jpg)

Facebook

Facebook Linkedin

Linkedin